Weaving is one of the oldest textile arts, and it forms the foundation of many fabrics used around the world today. At the core of this technique lies the interaction between two distinct sets of yarn: the warp and the weft. The yarns that run lengthwise on the loom are called the warp threads, while the yarns that go across from side to side are known as the weft or filling yarns. Crosswise yarn weaving is known as weft weaving, and it plays a crucial role in determining the texture, strength, and appearance of woven fabrics.

Understanding Crosswise Yarn Weaving

What Is Crosswise Yarn Weaving?

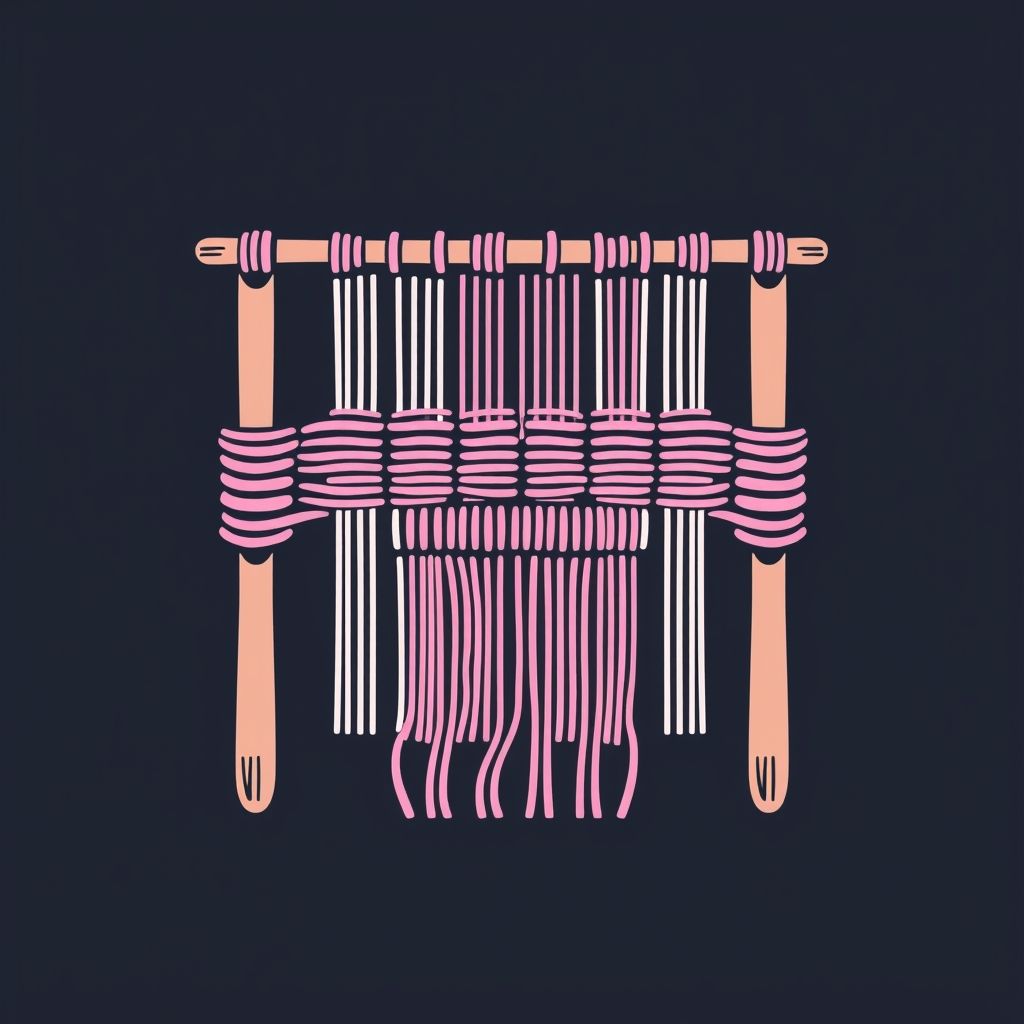

Crosswise yarn weaving refers specifically to the weft threads that pass over and under the warp threads during the weaving process. These weft threads move perpendicular to the warp and are inserted with each pass of the shuttle. The technique of crossing yarns in this manner is fundamental to creating woven structures and is used in everything from simple cloth to complex textile patterns.

Terminology of Weaving Components

- Warp: The vertical yarns held in tension on the loom.

- Weft: The crosswise yarns woven over and under the warp yarns.

- Shuttle: A tool used to carry the weft yarn across the loom.

- Shed: The space between raised and lowered warp threads through which the weft passes.

- Beater: Used to push the weft into place after each pass.

Function and Importance of Weft Yarns

Structural Role in Fabric

The weft is essential in forming the body of the fabric. Without the crosswise weaving action of the weft, there would be no interlocking system to hold the fabric together. The interlacing of weft and warp creates the weave pattern and determines how tight, loose, strong, or stretchy the fabric will be.

Weft Direction and Fabric Width

Weft threads run across the width of the fabric. The length of the weft determines how wide the fabric can be woven. This contrasts with the warp threads, which determine the fabric’s length. The ability to vary the type of weft yarn, its color, and its texture gives weavers considerable creative control over the final product.

Common Weaving Patterns Involving Crosswise Yarn

1. Plain Weave

This is the simplest and most common weaving pattern. In a plain weave, the weft thread alternately goes over one warp thread and under the next. The pattern continues row by row, creating a tight and balanced fabric. Both warp and weft are equally visible.

2. Twill Weave

In this pattern, the weft yarn passes over two or more warp threads and then under one or more. The offset with each row creates diagonal lines on the fabric surface. Twill weave is often used in denim and workwear fabrics.

3. Satin Weave

Here, the weft floats over several warp threads before interlacing under one. This results in a smooth, shiny surface, as the long floats of thread catch more light. The satin weave is commonly used for luxurious fabrics and formalwear.

Materials Used for Crosswise Weaving

Types of Weft Yarn

The weft yarn can vary widely depending on the desired outcome:

- Cotton: Soft and breathable, ideal for everyday fabrics.

- Wool: Warm and stretchy, used for blankets and outerwear.

- Linen: Crisp and strong, perfect for home textiles.

- Silk: Luxurious and smooth, preferred for elegant garments.

- Synthetic Fibers: Durable and easy to maintain, used in performance textiles.

Weft yarns can also be textured, dyed, or combined with different fibers to create unique designs and finishes.

Hand Weaving vs. Machine Weaving

Manual Weaving Techniques

In traditional hand weaving, the weft yarn is passed manually across the warp threads using a shuttle. This process is slower but allows for more detailed and customized patterns. It is common in artisan textiles and small-scale production.

Modern Looms and Automation

In industrial settings, automated looms rapidly insert weft yarns across thousands of warp threads per minute. These machines can be programmed to produce consistent patterns and accommodate high-volume output. Despite the speed, the principle of crosswise yarn weaving remains unchanged.

Special Applications of Weft Weaving

Decorative Tapestry Weaving

In tapestry, the weft yarns are used more freely and artistically. They may not go all the way across the fabric, allowing the weaver to create images and designs within the woven structure. The crosswise weaving technique becomes a medium for visual storytelling.

Double Weaving and Reversible Fabrics

Double weaving uses two sets of warp and two sets of weft to create fabrics with two layers. The weft yarns play a vital role in connecting these layers, often creating reversible or insulating fabrics used in garments or upholstery.

Challenges in Crosswise Yarn Weaving

Maintaining Tension

One of the most important aspects of effective crosswise weaving is keeping even tension. Uneven weft tension can result in puckered or distorted fabric. Regularly adjusting the loom and being consistent with the shuttle movement helps solve this issue.

Weft Breakage

Especially when using delicate or older threads, weft yarns can break during weaving. It’s essential to use yarns suited to your loom and maintain proper handling techniques to avoid this problem.

Color Changes and Striping

While changing weft colors can add visual interest, abrupt or poorly planned transitions may disrupt the design. Planning ahead and weaving in ends securely ensures a cleaner finish.

Why Crosswise Weaving Matters

Durability and Flexibility

The weft contributes significantly to the strength of the fabric. The crosswise direction allows fabrics to bend and flex differently from the warp direction. This is critical when choosing materials for garments, upholstery, or industrial use.

Creativity in Design

Because the weft is often more visible on the fabric’s surface, it serves as a canvas for creative expression. From colorwork to texture, the crosswise yarn opens a path for unique patterns and personal touches.

Historical and Cultural Significance

Weaving has deep roots in cultures across the world. Crosswise weaving is found in Navajo rugs, African kente cloths, Asian silk fabrics, and countless other textiles. Each weaving tradition carries specific techniques, many of which highlight the artistry of weft yarn use.

Crosswise yarn weaving, known as weft weaving, is fundamental to the fabric-making process. Whether done by hand or machine, it plays a central role in forming textiles of all kinds. From plain weaves to intricate tapestry, the way weft yarns interlace with warp threads defines the structure, appearance, and purpose of the final fabric. Understanding this process allows crafters, designers, and textile enthusiasts to appreciate the balance of technique and artistry involved. As weaving continues to evolve, the timeless value of crosswise yarn weaving remains at the heart of textile creation.