In traditional and modern agricultural practices, tilling the soil effectively is one of the most important steps in preparing the land for planting. One of the most widely used implements for this purpose is the moldboard plow. This essential tool is made up of several components, each with a specific role that contributes to the overall performance of the equipment. Among these components, the beam is a fundamental part of the moldboard plow. While often overlooked, the beam plays a crucial role in the alignment, stability, and efficiency of the plowing operation. Understanding the function of the beam helps farmers and equipment operators maintain optimal performance in fieldwork.

Overview of Moldboard Plow Components

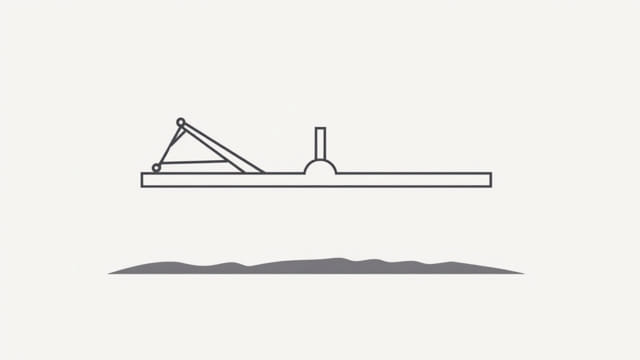

Before diving into the specific role of the beam, it is useful to understand the overall structure of a moldboard plow. The plow consists of several integrated parts that work together to turn over the soil and prepare a clean seedbed. These parts include:

- Moldboard: The curved metal plate that turns the soil.

- Share: The cutting edge that slices through the soil.

- Landside: The flat piece that stabilizes the plow against the furrow wall.

- Frog: The central part where the moldboard, share, and landside connect.

- Beam: The long horizontal part that connects the plow bottom to the frame or the tractor.

- Standard or Shank: The vertical support attached to the beam, holding the bottom assembly.

What Is the Beam in a Moldboard Plow?

Physical Description and Location

The beam in a moldboard plow is typically a sturdy horizontal bar made of heavy-duty steel. It runs along the length of the plow and connects all the bottoms (plowing units) to the main frame. The beam may be fixed or adjustable, depending on the design and manufacturer.

Beam Variations

There are different types of beams depending on the size and capacity of the plow:

- Single-Beam Plow: Used in simpler, lighter plows suitable for smaller fields or animal-drawn use.

- Multi-Beam Plow: Found in modern tractor-drawn plows, with multiple bottoms attached along the beam.

Primary Functions of the Beam

1. Structural Support

One of the main functions of the beam is to provide structural support for the entire plow. The beam holds the standards (shanks), which in turn support the plow bottoms. This alignment ensures that all parts maintain proper depth and angle during operation. A well-constructed beam keeps the plow steady even under tough field conditions, ensuring consistent plowing depth.

2. Proper Spacing Between Bottoms

In multi-bottom plows, the beam determines the spacing between each bottom unit. This spacing is critical for even furrow formation and proper soil turnover. Incorrect spacing can lead to inefficient plowing or missed patches of unturned soil.

3. Connection to the Tractor or Draft Source

The beam connects to the plow frame, which then links to the tractor or other draft sources like oxen. The beam ensures that pulling force is transmitted effectively from the draft source to the plow bottoms. The strength of the beam allows it to withstand the tension and stress during operation.

4. Maintains Line of Draft

The line of draft refers to the ideal path through which force is applied to move the plow through the soil. The beam ensures that this line remains straight and aligned, preventing unnecessary wear and helping conserve fuel or energy. An aligned draft line also minimizes strain on the animals or tractor used for pulling.

Importance of Beam Alignment and Maintenance

Effects of Misalignment

If the beam is bent or improperly aligned, the plow will not operate efficiently. Problems may include:

- Uneven furrow depth

- Increased drag and fuel consumption

- Excessive wear on moldboards and shares

- Difficulty in steering and guiding the plow

Maintenance Tips

To ensure optimal beam performance:

- Inspect regularly for bends, cracks, or corrosion

- Check the attachment bolts and tighten as needed

- Use rust-preventive coatings if storing the plow for extended periods

- Ensure proper alignment before fieldwork begins

Advantages of a Well-Designed Beam

A well-designed and properly maintained beam enhances the overall efficiency of the moldboard plow. Some of the key benefits include:

- Uniform soil turnover leads to better seedbed preparation

- Reduced operator fatigue as the plow runs smoothly without excessive manual adjustments

- Improved soil aeration by maintaining consistent plowing depth

- Enhanced durability protecting other plow components from stress

Modern Improvements and Beam Design

Material Strength

Modern plow beams are often made from high-tensile steel or reinforced alloys, which improve strength without adding unnecessary weight. This makes the plow easier to maneuver while still providing stability.

Adjustable Beams

Some modern plows come with adjustable beams that allow farmers to change the spacing between bottoms. This flexibility is useful for different soil types, crop spacing requirements, or tractor sizes.

Hydraulic and Reversible Designs

Advanced moldboard plows now include hydraulic systems that assist in adjusting the beam’s angle or reversing the plow for alternate furrows. These innovations save time and labor while increasing precision.

Role of Beam in Sustainable Agriculture

Fuel Efficiency

By ensuring smooth movement and alignment, a sturdy beam contributes to less fuel consumption, especially in mechanized plowing. This supports cost savings and environmental sustainability.

Soil Health

Consistent tillage depth and soil turnover allow for better water infiltration and root development. A reliable beam contributes to this consistency, helping promote healthier crop growth in the long term.

In summary, the beam of a moldboard plow serves a vital function in both traditional and modern farming. It provides structural support, ensures alignment, maintains proper spacing, and facilitates effective power transfer from the draft source. Proper maintenance and understanding of the beam’s role not only enhance plowing performance but also support sustainable farming practices. As farming technology continues to evolve, innovations in beam design will remain essential for increasing productivity, efficiency, and soil health across agricultural landscapes.