Farming tools have evolved over centuries, but the moldboard plow remains one of the most essential implements for traditional soil preparation. For farmers who use vintage or classic equipment, International moldboard plows originally produced by International Harvester are still valued for their durability and performance. Maintaining these plows involves sourcing the correct International moldboard plow parts, which are key to keeping the machinery functional and efficient during tilling operations.

Understanding the Moldboard Plow

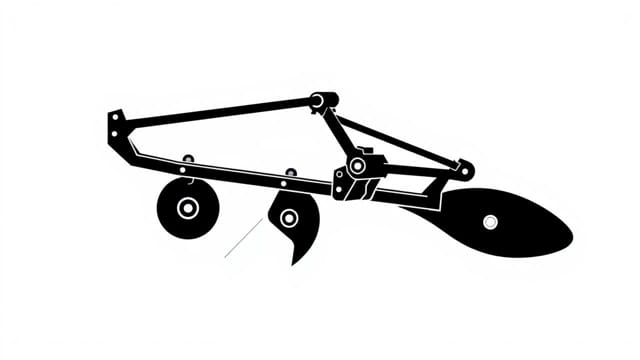

The moldboard plow is a tool designed to turn over the upper layer of soil, bringing fresh nutrients to the surface while burying weeds and residues. It is primarily used for primary tillage and is well-suited for heavy soils. The moldboard plow gets its name from the curved metal blade that cuts through and flips the soil.

International Harvester manufactured several models of moldboard plows during the 20th century. These plows, though now considered vintage, are still widely used due to their sturdy construction. To keep them running, understanding and replacing key moldboard plow parts is essential.

Major Parts of an International Moldboard Plow

A moldboard plow consists of several key components, each of which plays a specific role in the soil-turning process. Replacing or maintaining these parts ensures smooth operation and consistent plowing depth.

1. Share

The share is the cutting edge of the plow, located at the bottom of the moldboard. It slices horizontally through the soil and is usually the first component to wear out. For International plows, replacement shares are available in different styles to match specific models and soil conditions.

2. Moldboard

This is the large curved plate that lifts and turns the soil cut by the share. Moldboards come in various shapes general purpose, slat, or stubble each suited to different soil textures and moisture levels. Replacing a worn moldboard ensures consistent soil turnover and prevents clogging.

3. Landside

Located opposite the moldboard, the landside helps keep the plow in position and resists the lateral pressure of the soil. It also adds stability during deep plowing. Regular inspection is important as a worn landside can lead to uneven furrows.

4. Frog

The frog is the central piece to which the moldboard, share, and landside are attached. It acts as the framework and determines how the parts align. If damaged or cracked, it must be replaced to avoid misalignment and excessive wear on other parts.

5. Shins

Shins are bolted onto the front edge of the moldboard and serve to protect it from premature wear, especially in abrasive soils. They are cost-effective to replace and help extend the life of the moldboard.

6. Standards and Beams

The standard holds the bottom assembly and connects it to the beam, which links the plow to the tractor. Ensuring these parts are straight and undamaged is vital for maintaining the correct plow angle and depth.

Finding Replacement International Moldboard Plow Parts

Though International Harvester no longer exists as a brand, replacement parts for their moldboard plows are still available through agricultural supply dealers, vintage implement stores, and online platforms specializing in antique farm equipment.

Where to Source Parts

- Tractor salvage yards and used farm equipment dealers

- Online marketplaces specializing in vintage implements

- Local co-ops and farm service centers with historic inventories

- Third-party manufacturers who produce compatible aftermarket parts

When buying parts, always match the part number or plow model to ensure compatibility. International plows such as the 311, 412, or 720 series may have different dimensions and bolt patterns, even if the parts look similar.

Why Use Original or Compatible Parts?

Using genuine or precisely manufactured replacement parts is crucial for performance and safety. Parts that don’t fit correctly can lead to uneven wear, improper soil turnover, and even damage to the tractor or operator risk.

Advantages of Quality Replacement Parts

- Better fit and alignment for smoother plowing

- Extended lifespan of the implement

- Improved field efficiency and fuel usage

- Reduced risk of breakdown during critical farming windows

Although some cheaper alternatives exist, it’s recommended to invest in trusted brands or certified components to ensure long-term usability.

Maintenance Tips for Moldboard Plow Parts

Even with quality parts, routine maintenance plays a big role in how well the plow performs season after season. Inspecting and cleaning parts after each use helps avoid corrosion and wear.

Maintenance Checklist

- Clean soil and debris off all metal surfaces after plowing

- Oil the share, moldboard, and landside to prevent rust

- Check bolts and fasteners for tightness and wear

- Inspect for cracks or bends in the frog, beam, or standard

- Replace any worn or broken parts before the next use

Storing the plow in a dry, covered area during off-season months also prevents weather damage and extends part life.

Modern Uses of International Moldboard Plows

While modern conservation tillage and no-till farming have gained popularity, the moldboard plow is still widely used in certain conditions. For example, it remains valuable for breaking new ground, burying heavy crop residue, or managing weed infestations in high-residue fields.

International moldboard plows continue to be favored by small-scale and traditional farmers who appreciate their simplicity and reliability. With proper parts and care, these machines can remain productive for decades.

Keep Your International Moldboard Plow Working

Maintaining an International moldboard plow requires a good understanding of its parts and a commitment to regular upkeep. From shares and moldboards to frogs and landsides, each component has a unique role in field performance. By sourcing the right replacement International moldboard plow parts and following maintenance best practices, farmers can preserve the value and effectiveness of their trusted equipment. Even as farming technology advances, the moldboard plow continues to prove its worth especially when it’s kept in top working condition with the right parts and care.